Alternative Fuels and Raw Materials

Plastroots play a crucial role in transforming waste into energy by producing and supplying high-quality Refuse-Derived Fuel (RDF). Our operations are aligned with national goals of landfill reduction, sustainable waste management and promoting alternative fuels for industries.

We actively work with municipal corporations and urban local bodies to clear legacy waste from landfills, ensuring cleaner cities and reclaimed land. This waste is processed into RDF, which we supply to cement industries and other co-processing units based on their specific calorific and material requirements.

With a robust supply chain across multiple locations in India, we ensure timely and efficient delivery of RDF that meets quality benchmarks. Our services not only support the circular economy but also help industries reduce their dependency on fossil fuels.

Work Process Flow

Nation-Wide Sourcing Networks

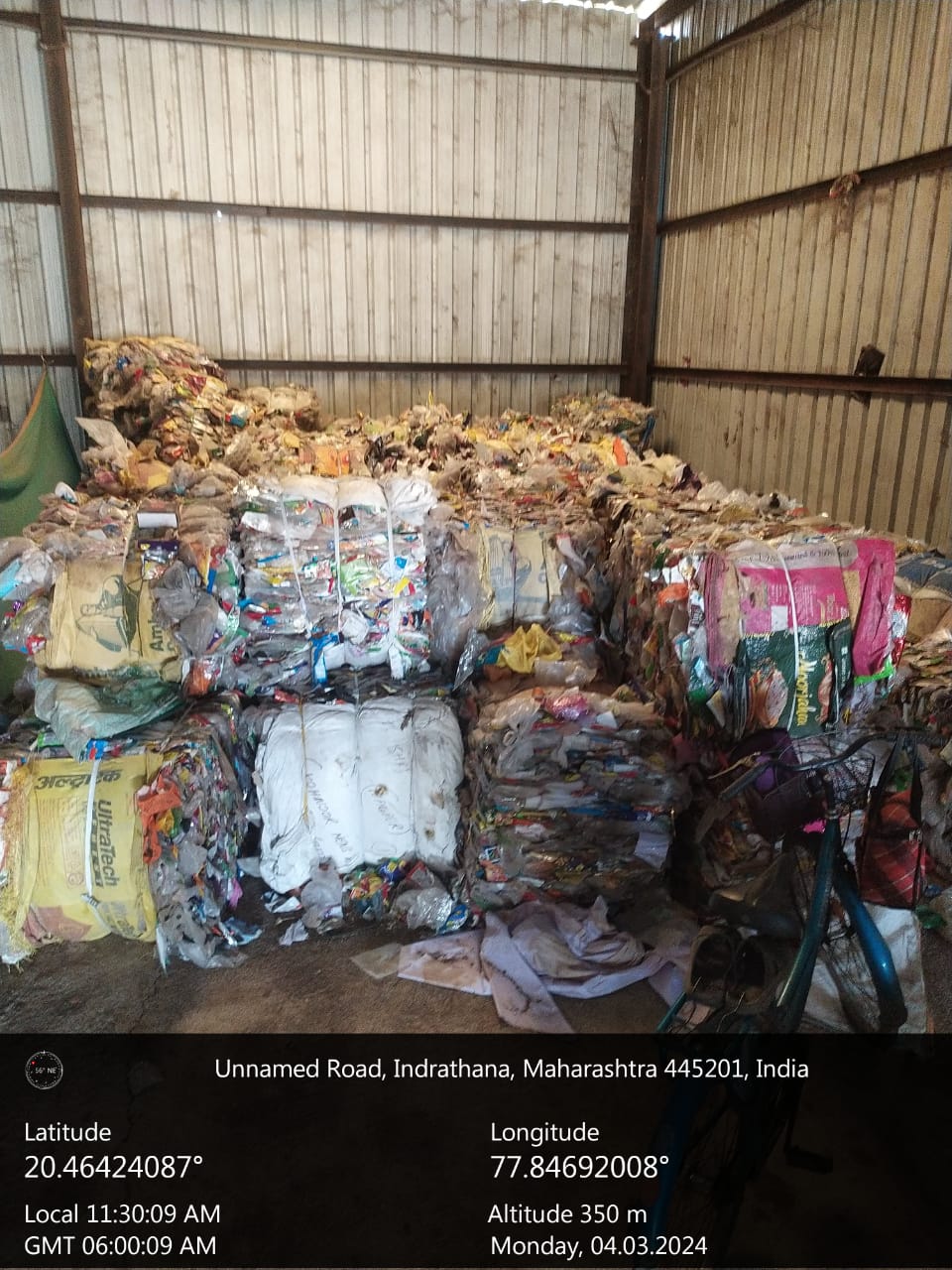

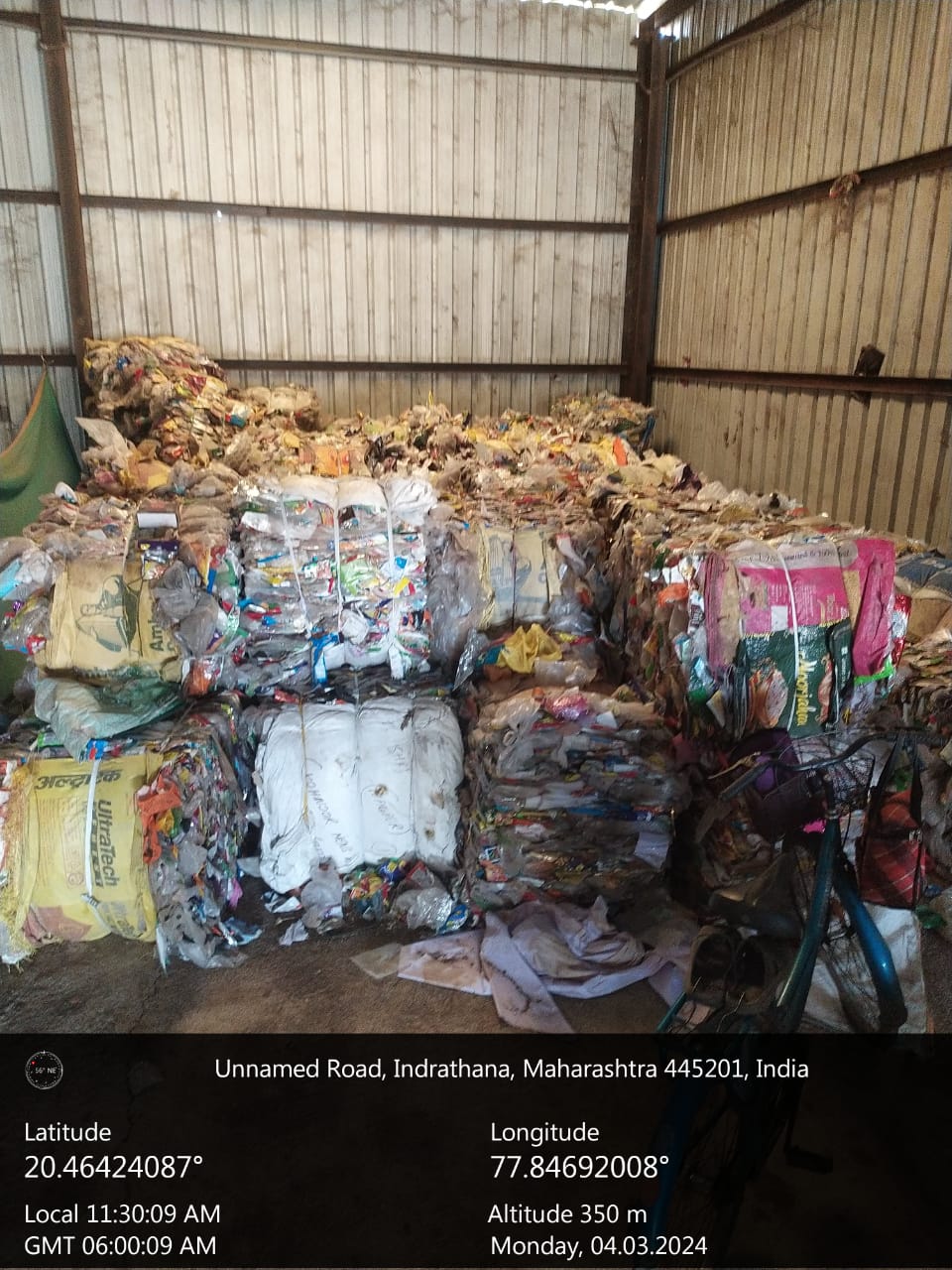

Collection of waste through ULB’s, Processing Sites, Landfill sites & Transferring Points.

Transportation to Disposal Facilities

Either to co-processing sites or disposal Industries Authorized by Respective Pollution Control Board.

Compliance and Certifications

Regulatory Proficiency with Real Time Tracking & Reporting Capabilities.

Assessing waste doesn’t have to be complicated. With Plastroots, you’ll experience a streamlined and efficient assessment process. We start by assessing the waste streams available in our region. Through careful analysis, we identify suitable materials for RDF production. These include non-recyclable plastics, paper, cardboard, wood, and other combustible waste. We prioritize materials with high energy content and low contamination levels for optimal RDF quality.

We maintain strict quality control measures throughout the RDF production process to ensure consistency and efficiency. Our team conducts regular testing to verify the calorific value and composition of the RDF, meeting industry standards and requirements.

First, we gather waste materials from various sources such as Urban Local Bodies/ Municipalities, Industries, and Commercial establishments. These materials include non-recyclable Plastics, paper, cardboard, wood, Bio Mass, Metals & Glass.

By supplying cement industries with RDF, Bio-Mass & Plastic Waste we contribute to reducing their reliance on traditional fossil fuels such as coal and natural gas. These only conserves finite resources which reduces greenhouse gas emissions and air pollution, promoting a cleaner and more sustainable environment.

We implement rigorous testing and monitoring procedures to maintain product integrity and consistency. Each batch of RDF is meticulously documented, allowing for traceability throughout its lifecycle. From its origin to its destination in cement industries, we ensure full transparency and accountability.

Number we Have Achieved

Our Partners